Description

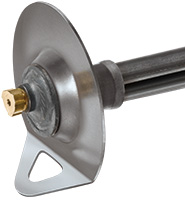

The Hydrabolt is a fabricated steel tube, “C” shaped in cross section, and sealed at both ends. At one end a hydraulic nipple, with integral non-return valve, allows connection to a hydraulic pump.

The Hydrabolt is a fabricated steel tube, “C” shaped in cross section, and sealed at both ends. At one end a hydraulic nipple, with integral non-return valve, allows connection to a hydraulic pump.

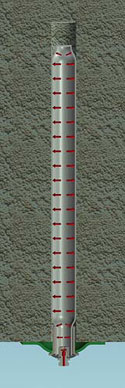

After drilling a support hole in the rock to the required diameter and length, the Hydrabolt is inserted and a pump is used to expand the tubular rockbolt radially with water at pressures typically 25MPa (3500psi). Frictional resistance between the wall of the hole and Hydrabolt provides outstanding pull-out resistance.

The Hydrabolt has been designed to facilitate ease of installation and to provide the user with immediate support and a safe working environment. Unlike other designs, the Hydrabolt incorporates a check valve to prevent the fluid from being released once the inflating nozzle is removed. This system provides a better grip as the clamping inside the hole adapts to the shape, size and irregularities of the hole and distributes the clamping force evenly throughout the length of the hole. As the installed Hydrabolt is sealed the internal corrosion is self-inhibiting.

The patented design of the Hydrabolt valve provides a visual method of verifying the correct installation of the roofbolts. The integral load indicator indicates that the Hydrabolt has been correctly installed by popping forward once the Hydrabolt has been installed with the correct internal pressure; secondly the colour of the load indicator identifies which length of Hydrabolt has been installed. The load indicator also confirms whether a Hydrabolt or X-Pandabolt has been installed.

The patented design of the Hydrabolt valve provides a visual method of verifying the correct installation of the roofbolts. The integral load indicator indicates that the Hydrabolt has been correctly installed by popping forward once the Hydrabolt has been installed with the correct internal pressure; secondly the colour of the load indicator identifies which length of Hydrabolt has been installed. The load indicator also confirms whether a Hydrabolt or X-Pandabolt has been installed.

Hydrabolt indicator

Hydrabolts can now be fitted with a new button and indicator where the load indicator protrudes from the button after correct pressurisation. This allows for better visibility of the indicator when checking for correct installation. This system is compatible with the new Self-auditing Jackpot.

Advantages of Hydrabolts

Advantages of Hydrabolts

- Quick and easy to install

- Wide expansion range

- Patented non-return valve which limits “spring-back” giving increased pull-out resistance

- Pressurising done remotely

- Not affected by blasting vibrations

- No resin or grout required

- No parts to lose in transport

- Not susceptible to rock strength

- Load distributed evenly over entire length of hole

- Provides immediate support

Range

Three models of the Hydrabolt are currently available and can be manufactured in lengths ranging from 0.9 to 3.0 meters in increments of 0.3 meters. Non-standard lengths can be accommodated upon request.

|

Model

|

Nominal diameter (mm)

|

Recommended hole diameter (mm)

|

Maximum Load Capacity (ton)

|

Typical Bond Length (mm)

|

|

Hydrabolt NT

|

26

|

32–36

|

8.0

|

250

|

|

Hydrabolt Normal

|

26

|

32–36

|

10.0

|

250

|

|

Hydrabolt Ø29

|

29

|

34–40

|

10.0

|

300

|